Capabilities

Engineering Capabilities

Project Management:

Project management can be defined as the planning, organization, directing, and controlling of resources for a defined period of time to complete specific goals and objectives. While this sounds simple enough in theory, many people who have managed projects can attest that it is never quite as easy as it sounds. Magnitude Engineering can help you manage your project so you can focus on your core activities.

Popular tools – Microsoft Project

Systems Engineering:

System engineering can be defined as an interdisciplinary process where stakeholder needs are satisfied in a high-quality, trustworthy, and cost and schedule efficient manner throughout the entire life cycle. It is a top-down/bottom-up development approach where all phases of the life cycle as a whole are considered throughout the process. Magnitude Engineering can help you apply sound systems engineering principles through the development of system architecture, creation of detailed specifications, and application of in-depth design reviews.

Product Development:

Developing a product from a concept to a finished product accepted by the customer can be an overwhelming task. Magnitude Engineering can help guide you through the process from product planning and identifying customer needs, to concept generation and selection, prototyping and testing, and full-scale production.

Value Engineering:

Simply developing and manufacturing new products may not be enough to remain competitive in today’s global landscape. Customers are increasingly demanding more and more value as a prerequisite to making a purchase. Understanding and optimizing value from the eyes of your customer can be the key that unlocks customer satisfaction and additional profit for your organization. Magnitude Engineering can help you deliver more value through the use of tools such as functional analysis, design for manufacturing and assembly, and lean development and manufacturing principles.

Reliability Engineering:

Reliability can be defined as the probability that a product fulfills its intended use without failure for a specified period of time under stated conditions. Designing and manufacturing products with high reliability is a great way to build customer loyalty while reducing costs. Magnitude Engineering’s reliability engineering experience can help you improve your products whether they are in the concept, development, production, or maintenance phase of their life cycle through the use of tools such as failure modes and effects analysis, highly accelerated life testing, and statistical analysis.

Popular tools – Reliasoft Weibull++, Reliasoft ALTA

Sample page from failure

modes and effects analysis (FMEA)

Mechanical Engineering:Mechanical engineering is one of the oldest and broadest fields of the engineering profession, yet it is just as relevant today as it was 100 years ago. Application of mechanical engineering principles such as materials science, solid and fluid mechanics, thermodynamics, heat transfer, and control theory are everywhere. Magnitude Engineering’s broad experience can help you apply these principles to the most challenging problems.

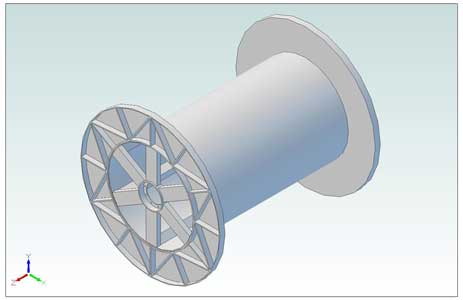

Popular tools – Autodesk Autocad, Dassault Systems Solidworks, PTC Pro-Engineer, Alibre Design, Design Simulation Technologies Working Model

3D CAD model of a hose drum using Alibre Design Analysis, Modeling, and Optimization:

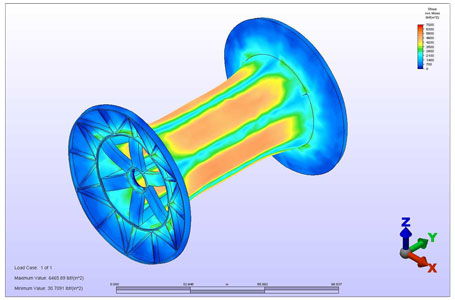

Designing a product that simply works is one thing. Developing one that is optimized for performance, weight, reliability, cost, or any other parameter of interest is quite another. Detailed modeling using tools such as spreadsheets, programming languages, advanced math packages, or finite element analysis makes it easier and more cost effective to try multiple alternatives and optimize your design before building a single prototype. In many cases, modeling can provide insight into phenomenon that are difficult, costly, or impossible to measure otherwise. Magnitude Engineering can develop models based on first principals, empirical data, or a combination of both.

Popular tools – Microsoft Excel, Mathworks Simulink, PTC Mathcad, Ansys,

Autodesk Algor

Deflection analysis of a frame using Mathcad

Finite element stress analysis of a hose drum using Algor

Examples:

Fixture for spinning excess paint from housings (cover removed for clarity)

Automated spring life cycle test fixture

Speaker positioning mount

Manufacturing Capabilities

- Prototyping and Low Volume Machining

- CNC Milling

- Turning

- Artsoft Mach 3 Software

- Alibre CAM Software

- Vectric Cut 2D Software

Linear motion bracket

Lightweight racing fork mount

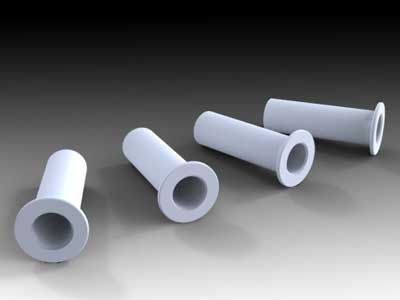

Precision automotive door hinge bushings